Gold Jewelry Casting

Professional Gold Casting Jewelry Services From Casting House

Whether you are creating an engagement ring, wedding band, reproduction of a favorite piece of jewelry, a customized piece for a client, or a new piece for your jewelry store, gold is often the preferred metal of choice. The gold casting jewelry services offered by Casting House allow you to create high-quality pieces of jewelry.

The Gold Casting Jewelry Process: A Closer Look

Gold casting is a part of the jewelry creation process. It allows designers and jewelry stores to take an idea or design, create a mold, and eventually end up with a physical reproduction of the final product.

The gold casting process involves the following steps:

- Wax model and casting preparation. Using the design, a wax model is carved or printed to represent what the finished piece will look like in three dimensions. These are connected to a wax stem by a sprue. This will form the channel through which the molten gold will flow once the mold is created.

- Investment. The wax stem and the attached models are placed in a special frame called a flask and surrounded by an investment material. Once the investment material sets, it hardens into the mold for the jewelry.

- Burnout. After the investment material hardens, the flask is placed in a special kiln to burn away the wax, which leaves a cavity in the investment material that becomes the final mold.

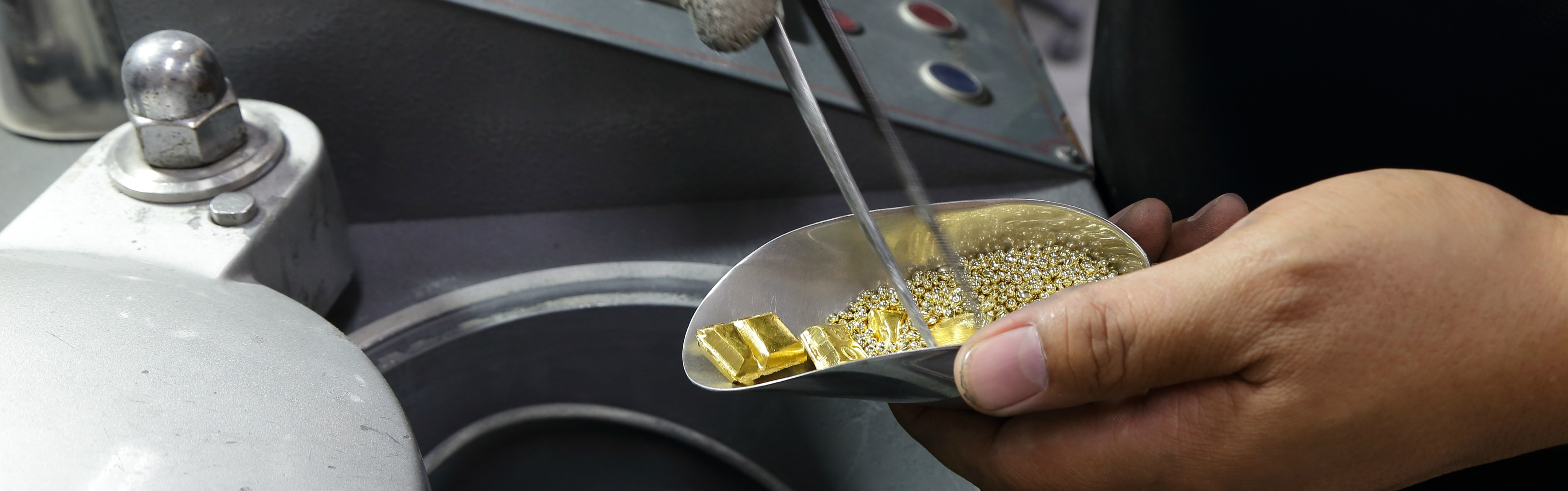

- Melting. The gold is melted, and depending on the alloy or type of gold used, temperatures can range from 1,617 degrees Fahrenheit and 2,006 degrees Fahrenheit. Gold can be combined with other metals like silver, copper and palladium to create different alloys of varying color and hardness.

- Casting. The liquid gold can be poured directly into the mold, but various techniques can be used to ensure a higher-quality casting. Centrifugal casting, vacuum-assisted casting or pressure casting can be used to ensure the gold flows into every area of the mold evenly.

- Divesting. Once the metal cools, it needs to be removed from the investment material. This can be done through physical or chemical means. Each casting is cleaned and polished, and the sprues are cut off for recycling.

Designers and jewelry stores have the option to cast their own gold jewelry, but the process is time-consuming and complicated. Using a gold casting company, like Casting House, allows jewelry designers and jewelry stores to create unique pieces of jewelry without having to learn the complex and tedious casting process.

What Gold Metals Do We Work With When Offering Gold Casting Jewelry Services?

The casting gold experts at Casting House are always working to offer clients the ability to work with the newest, most popular metals. Our selection of gold metals constantly changes to meet our clients’ needs.

There are three main types of gold that typically are used in jewelry manufacturing:

- White Gold — This is yellow gold that is generally mixed with nickel and then plated with rhodium: A silvery white metal that gives white gold its shine and luster. The plating process involves dipping the jewelry into a solution containing rhodium, then running an electric current through it to bond the rhodium particles to the surface. This plating process needs to be redone periodically because the rhodium will wear off over time. White gold can also be made by mixing gold with palladium for people who are allergic to nickel.

- Yellow Gold — Yellow gold is typically alloyed with copper, silver or zinc, with the gold taking on a more reddish or greenish hue depending on the metal of which it is mixed.

- Rose Gold — The pinkish color of rose gold is the result of yellow gold being alloyed with different levels of copper and silver.

The following chart explains how much gold is present in the different karats:

- 24K = 99.9 percent gold

- 22K = 91.6 percent gold

- 18K = 75 percent gold

- 14K = 58.5 percent gold

- 10K = 41.7 percent gold

Some of the gold metals that we currently work with when it comes to gold casting jewelry services include:

- 10K or 14K Yellow Gold

- 18K Yellow Standard Gold

- 18K Yellow-Yellow Gold

- 22K or 24K Yellow Gold

- 14K or 18K White Standard Gold

- 14K or 18K White X-1 (rhodium optional) Gold

- 14K or 18K White with Palladium Gold

- 14K Rose Gold

- 14K Soviet Red Gold

- 14K or 18K Green Gold

Why Clients Trust Casting House With Casting Gold Services

Jewelry stores and jewelry designers all over the world trust Casting House to provide superior, professional gold casting jewelry services. We are a trusted gold casting company because of our vast experience, use of the latest technology and casting equipment, and our personalized approach to customer service.

Some of the reasons why clients have chosen Casting House for their gold casting jewelry services include:

- Use of a multi-step quality assurance process

- Option to use multiple casting services that include individual laser review, casting preparation, and final magnetic tumbling for a finished, polished look

- Use of high-quality photopolymer technologies and cutting-edge molding

- Ability to create first-rate reproductions from silicone molds

- Fast turnaround on casting orders

- Easy submission process for wax molds for casting

- Ability to place bulk orders

- Use of eco-friendly reclaimed precious metals for gold castings

- Assignment of a personalized job coordinator who will work with you to place your order and match you with the services you need to get an outstanding product

Let Casting House save you time by handling your gold jewelry casting. Contact us to speak with an account rep to see how we can help you.